Table Of Content

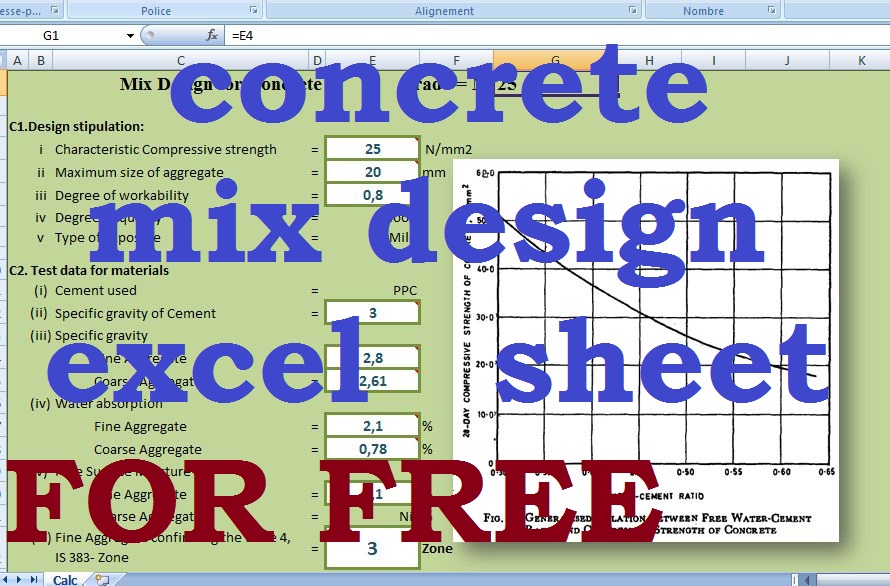

Therefore, mix design involves several key aggregate specific gravity measurements. Once the ingredients have been identified, the proportions must be determined. The proportions are generally expressed as a ratio of cement to water to aggregate and can vary depending on the desired properties of the concrete. Rheology modifying admixtures increase the viscosity of the concrete while still allowing it to flow without segregation.

Step 6: Determination of Coarse Aggregate Content

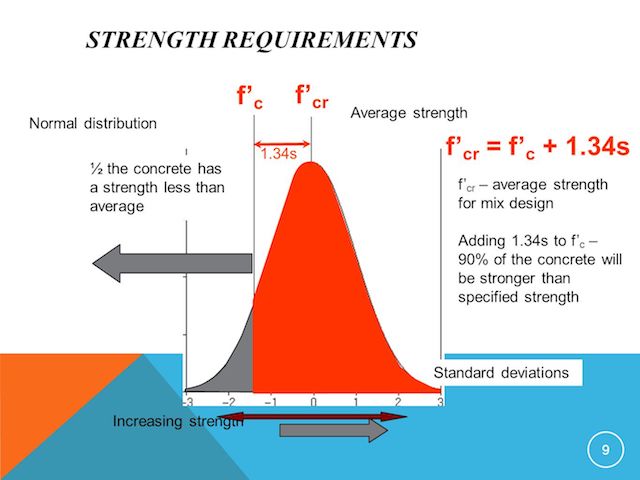

While these specifications are quite logical to a small contractor or individual who buys portland cement in 94 lb. Sacks, they do not have much meaning to the typical pavement contractor or batching plant who buys portland cement in bulk. As such, specifying cement content by the number of sacks should be avoided. Here, we find the water-to-cement ratio that achieves both the strength and durability requirements. Specifically, there are substantial differences between laboratory and field conditions. For instance, mix testing is generally done on small samples that are cured in carefully controlled conditions.

What is the tolerance for compression test results of concrete, according to the standards?

Depending on the type of construction, you choose the desired value of slump. According to ACI 211 Report for the proportioning of concrete mixtures, the following value can be used as a guide for slump values. If you have previous data on a certain mixture design, you can use these data to find mix design that suits your situation. When there are no existing records or they are insufficient, the concrete mixture must be determined by trial mixtures.

Step 3: Determine the Water-to-cement Ratio (W/C)

Mix & Match Design Co. is all about making interior design approachable for everyday living. We love coming alongside our clients to help them create warm, functional homes that reflect their personality and style. The calculate mix design for concrete following step to be followed. Long-term durability is at least as important as placeability and strength, but it is sometimes sacrificed if there are compromises to be made.

Ice Spice brought her Y2K-loving Gen Z approach to the French tip obsession, painting chocolate milk-colored lacquer on duck-shaped nails. Create a Pinterest Board specifically for the room you’re designing and take a week to Pin what you love. Don’t only pin things with the style you think you’re going for.

Different tests should be done to determine the required properties of the concrete, such as strength, durability, air content, and water-cement ratio. Understanding the process of concrete mix design and mastering the strategies for creating mixed designs is essential for achieving quality construction. It is the key to successful and cost-effective construction projects. In this article, we will discuss the benefits of mastering concrete mix design, the key components of concrete mix design, and the strategies for mastering it. We will also discuss implementing proven strategies and the necessary resources for mastering concrete mix design. Also included are detailed instructions for incorporating high-performance admixtures as submittals for construction projects.

Bryan and Catherine Williamson's Remodel Featured on Magnolia Network - Columbus Monthly

Bryan and Catherine Williamson's Remodel Featured on Magnolia Network.

Posted: Fri, 18 Aug 2023 07:00:00 GMT [source]

There are many grade of nominal mix concrete like M-5, M-7.5, M-10, M-15 and M-20. Design mix – Design mix is a process to prepare concrete by testing all necessary properties (like properties of cement, fine aggregate and coarse aggregate) of concrete ingredients. Establishing quality control processes is also important for mastering concrete mix design. This involves testing the concrete mixes and ensuring they meet the desired specifications. Contractors should also inspect the finished products regularly and make any necessary adjustments. Creating mix designs for specific needs is also a key strategy for mastering concrete mix design.

Strategies for Mastering Concrete Mix Design

The unit weight of freshly mixed concrete is stated as a weight per volume. Corrosion inhibiting admixtures chemically mitigate the corrosive action of chlorides (often found in water) on reinforcing steel and prestressed strands in concrete. These design factors – function, cost and aesthetics – are mixed together in different ways in order to appeal to different target markets .

MIX directly imports of one of a kind unique found objects and furniture from around the world and produces a wide range of custom lighting, furniture and accessories. As we assumed the aggregate is a saturated surface dry condition, therefore no correction is required. Properly proportioned mixes will remain beautiful for many years. Use this handy concrete calculator to quickly calculate how many yards or bags of concrete you'll need for your project.

They should also study the properties of concrete and its behavior in different conditions. For contractors, understanding and mastering concrete mix design is essential for quality construction. With the right strategies, contractors can make the most of their concrete mixes and ensure that the end products meet their needs.

Combining the right materials in the right proportions and ratios is key to creating a concrete mix that produces excellent results. As such, mastering concrete mix design is essential for any construction project. Doing so offers several advantages, such as improved work efficiency, cost savings, and better quality control. Creating a concrete mix design involves identifying the desired properties of the concrete mix and determining the proportions of the ingredients needed to produce it. The properties are generally defined in terms of strength, workability, durability, shrinkage, and other characteristics of the concrete mix. Mix design selects, combines, and proportions different concrete components to obtain the desired performance.

Shop Mix-Century Modern Furnishing With Dann Foley at Revivals - Palm Springs Life

Shop Mix-Century Modern Furnishing With Dann Foley at Revivals.

Posted: Sat, 17 Feb 2024 08:00:00 GMT [source]

The summation of volumes of all components (such as cement, water, aggregate, etc) in the concrete mix is 1. Nominal mix specifies the fix proportion of the cement, sand and aggregates. We hope this helps you see how you can design a home you love without being boxed in by a design style. From Boho to Modern to Farmhouse and even Traditional we see white walls are very common. We love a pop of color, but when you love a ton of styles sometimes it’s best to run with a neutral wall and then get bold with accents.

Both are useful properties for cold weather concreting when the rate of cement hydration decreases with lower temperatures. 1- When concrete is produced using standard arbitrary proportions of concrete ingredients, it is known as nominal mix concrete. 2- The nominal mixture is a mixture taking into account all the ratios in the volume where the strength and cost of concrete and the strength of concrete vary. Concrete mix design involves a process of preparation in which a mix of ingredients creates the required strength and durability for the concrete structure. The American Concrete Institute (ACI) mix design method is but one of many basic concrete mix design methods available today. This section summarizes the ACI absolute volume method because it is widely accepted in the U.S. and continually updated by the ACI.

These values are then used to draw conclusions about how a mix will behave under field conditions. Despite such limitations mix design procedures can provide a cost effective and reasonably accurate simulation that is useful in making mix design decisions. Mix design is meant to simulate actual PCC manufacturing, construction and performance. Then, from this simulation we can predict (with reasonable certainty) what type of mix design is best for the particular application in question and how it will perform. This section covers mix design fundamentals common to all PCC mix design methods. First, two basic concepts (mix design as a simulation and weight-volume terms and relationships) are discussed to set a framework for subsequent discussion.

It is used to ensure that the concrete produced is of the highest quality and meets the requirements of a particular project. The components of concrete mix design are typically cement, water, aggregate, and admixtures. Design mix is a process to prepare concrete by testing all necessary properties (like properties of cement, fine aggregate and coarse aggregate) of concrete ingredients. Mastering concrete mix design also offers better quality control. By creating the right mix design and ensuring that all components are accurately proportioned and blended, contractors can ensure that the concrete produced is of the highest quality.

The hundreds of fixtures and finishes available at the Home Gallery™ design center have been professionally color-matched for foolproof coordination. Although this can take the guesswork out of selecting a backsplash that matches your countertops, you are not limited to one color studio! Maybe you love the cool grays of our Coastal Gray color studio, but you want to warm it up with rich hardwood floors. Rely on your design consultant to guide you through personalized color mixing. An older practice used to be to specify the cement content in terms of the number of 94 lb. This resulted in specifications such as a “6 sack mix” or a “5 sack mix”.